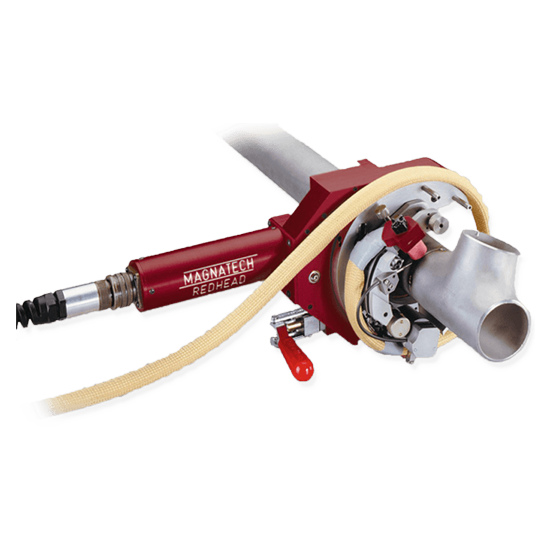

Description

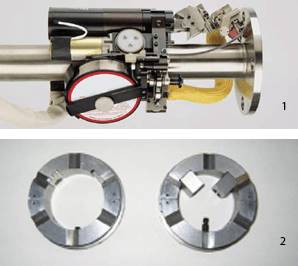

Guide Rings Mount Head on Pipe

Available for all nominal pipe sizes 48 mm –

356 mm ( 11/2� – 14�) and Tube sizes 44 mm – 127 mm (1.75� – 5� O.D.)

1. TILT AVC

(Adjustable) allows torch to be pivoted up to 60° for socket/fillet welds. Maintains arc length correction motion along tungsten electrode axis.

2. GUIDE RING ADAPTOR KITS

Allow Guide Rings to be used on smaller pipe sizes. Use with oversized Guide Rings on preheated pipe to prevent heat damage.

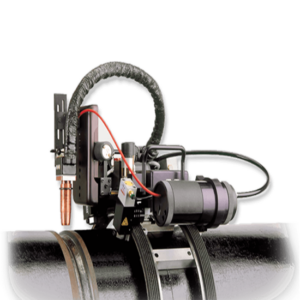

3. VIDEO ARC MONITORING

Various configurations allow remote operation

4. LOW PROFILE SPOOL KIT

Reduces radial profile of D Weld Head to 50mm (2�); Low Profile Wire Spool 0.5kg (1lb.) required.

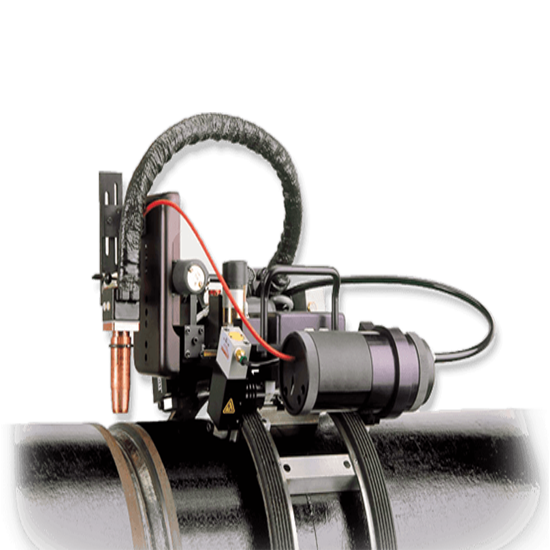

420 D-Head

| Specifications | ||

|---|---|---|

| Application | Multi-pass orbital GTAW pipe-to-pipe, pipe-to-fitting | |

| Cable length | 7.6 m (25’) standard. Extension cables available | |

| Pipe (tube) size range | 25 – 356 mm (1 – 14�) | |

| Filler wire module | Wire size | 0.8, 0.9, 1.0 mm (0.03�, 0.035�, 0.040�) |

| Max. speed capability | 2540 mm/min. (100 IPM) | |

| Spool size | 1 kg (2 lbs) std; 0.5 kg (1 lbs) low profile | |

| Oscillation module | Max. oscillation stroke amplitude | 16 mm (0.6725�) |

| Max. oscillation speed | 1520 mm/min. (60 IPM) | |

| Oscillation dwell | 0 – 1 second | |

| Cross seam adjustment | ± 6.4 mm (0.25�) | |

| Arc gap control module | 13 mm (0.5�) stroke. Additional mechanical adjustment allows welding heavier wall pipe | |

| Torch propulsion module | 250 mm (10 IPM) maximum rotation speed | |

| Water-cooled torch | 200 A continuous capability | |

| Torch adjustment capability | Torch lead/lag adjustment | ± 15 degrees (manual) |

| Torch tilt adjustment | ± 10 degrees (manual) | |

| Power supply compatibility | Pipemaster 515, Pipemaster 516 | |

| Dimensions/weights | ||

| Weight | 3.6 kg (8 lbs.) |

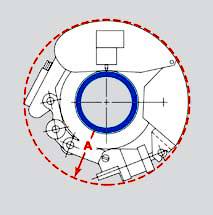

| Axial Clearance | Torch C/L to Rear Extremity: 220 mm (8.51�) | |

| Torch C/L to Front Extremity: 10 mm (0.41�) | ||

| “A� Radial Clearance Requirement for Pipe 44.45mm (1.75�) and larger | 64 mm (2.5�) with Standard Spool* 51 mm (2.0�) with Low Profile Spool* | |

| * For pipe/tube OD’s less than 44.45mm (1.75�), Radial Clearance Requirement increases with decreasing diameter. Contact Factory. | ||

Applications

- Fossil Power Plant Construction/Maintenance

- Steam Generation Equipment Fabrication

- Nuclear Power Plant Construction/Maintenance

- Chemical/Petrochemical Facility Construction Maintenance

- Shipyard Construction

- Gas Transmission Pipelines

- Process Piping

Features

- Full function Capability (Torch Rotation, Filler Wire Feed, Electronic Arc Gap Control, Electronic Oscillation)

- Broad size range

- Guide Rings available for standard Tube/Pipe sizes

- Waterproof Carry Case/Tool Kit standard

- Water-Cooled Torch uses standard Expendables

Guide Rings Mount Head on Pipe. Available for all nominal pipe sizes 48 mm – 356 mm ( 11/2� – 14�) and Tube sizes 44 mm – 127 mm (1.75� – 5� O.D.)

Reviews

There are no reviews yet.