Description

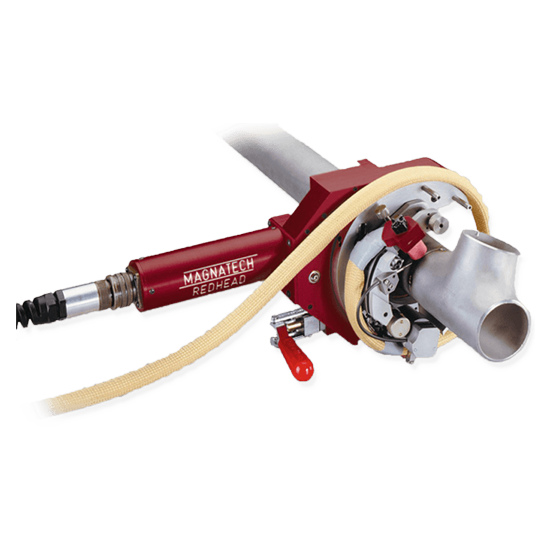

FLX-TRACK™

In addition to welding pipe, the T Head is also used for ID and OD welding on larger tanks, vessels, and ductwork.

- Flexible track allows mounting on complex curved surfaces

- Standard 2.3m (7.5′) Track sections bolt together for longer lengths

- Magnetic or Vacuum attachment

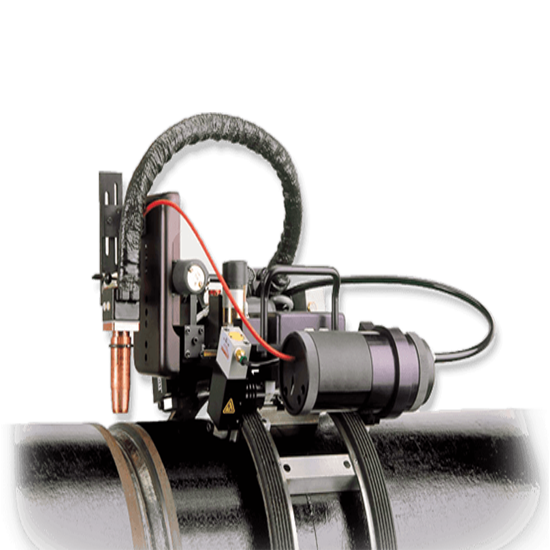

T-Head 419

| Specifications | ||

|---|---|---|

| Application | Multi-pass orbital GTAW pipe-to-pipe, pipe-to-fitting | |

| Cable length | 7.6 m (25’) standard. Extension cables available | |

| Pipe (tube) size range | 168 – 1524 mm (6 – 60â€?) and larger | |

| Filler wire module | Wire size Max. speed capability Spool size | Wire size: 0.8, 0.9, 1.0, 1.2 mm (.030�, .035�, .040�, .045�) 2540 mm/min. (100 IPM) 1 kg (2 lbs) standard |

| Oscillation module | Max. oscillation stroke amplitude Max. oscillation speed Oscillation dwell Cross seam adjustment | 16 mm (0.6725�) 1520 mm/min. (60 IPM) 0 – 1 second ± 6.4 mm (0.25�) fine adjustment ± 38 mm (1.5�) course adjustment |

| Arc gap control module | 13 mm (0.5�) stroke. Additional mechanical adjustment allows welding heavier wall pipe | |

| Torch propulsion module | 250 mm/min. (10 IPM) maximum rotation speed | |

Water-cooled torch | 300 A continuous | |

| Torch adjustment capability | Torch lead/lag adjustment Torch tilt adjustment | ± 15 degrees (manual) ± 10 degrees (manual) |

| Power supply compatibility | Pipemaster 515, Pipemaster 516 | |

| Dimensions/weights | ||

| Weight | 11.8 kg (26 lbs.) Single wire feeder without wire spool 13.4 kg (29.5 lbs.) Dual wire feeders without wire spools | |

| Axial clearance | Torch C/L to Rear Extremity: 4950 mm (19.5�) Torch C/L to Front Extremity: 290 mm (1.1�) | |

| Radial clearance | 250 mm (9.8�) | |

Applications

- Fossil Power Plant Construction/Maintenance

- Steam Generation Equipment Fabrication

- Nuclear Power Plant Construction/Maintenance

- Chemical Facility Construction/Maintenance

- Shipyard Construction

- Gas Transmission Pipelines

- Process Piping

Features

- WELD HEADS 800 SERIES 805, 810, 820, 830, 840, 860

- Collets for all tube sizes / fitting geometries

- Waterproof carry case standard

- Bench mount bracket

- Internal weld head cooling standard

- Convenient flip-up view port allows final inspection before welding

- Encoder motors provide precise, repeatable speed regulation

- “Jam� detection/protection. If rotation stops for any reason, it is instantly sensed and power to the motor is immediately interrupted.

- No more damaged motors or drive trains

- Standard 8 m (25’) hose pack length

- New rotation drive design tolerant of metal debris

- “Home� position switch automatically readies the head for removal following weld completion, and never requires adjustment

- Simple assembly makes field service straightforward

Reviews

There are no reviews yet.