Description

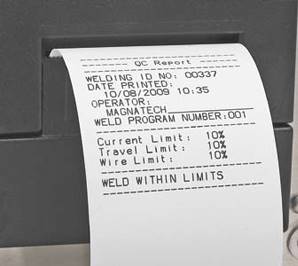

WELD MONITORING/QC

INTEGRAL WELD MONITORING SOFTWARE PROVIDES INSTANT INFORMATION ON WELD QUALITY

Acceptable limits are programmed for each critical weld parameter. At the completion of each weld, a printout records the weld ID number, date and time, the operator’s name and whether the weld was performed within the defined limits for acceptable weld quality. If any critical parameter falls outside the defined limits, the operator is immediately notified as to:

- Out of limit parameter

- Maximum deviation from programme value

- Maximum deviation time

QC reports are immediately printed following each weld using the built-in printer option. Or, they can be stored internally and downloaded periodically to a PC using a standard USB Flash Drive. Import weld programs and QC data directly into a Word® or Excel® spreadsheet document.

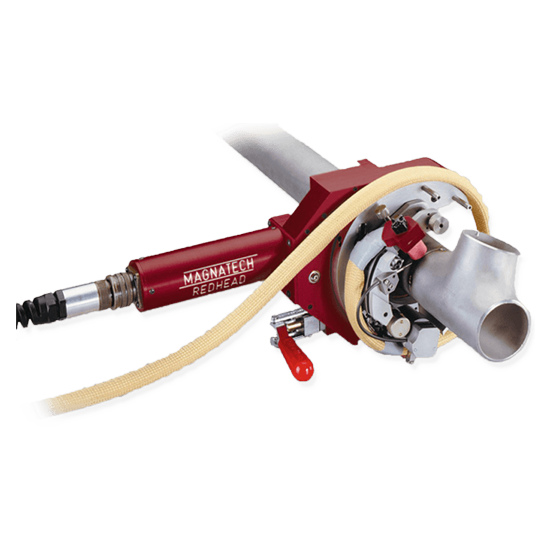

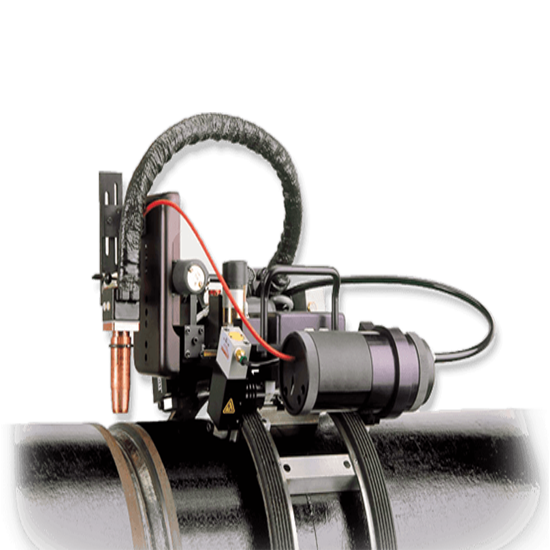

Tubemaster 514

| Specifications | ||

|---|---|---|

| Application | For use with many Magnatech weld head models (GTAW process), welding lathes, and dedicated weld systems | |

| Functions controlled | Welding current output/current pulsing, weld head rotation, Weld head wire feed speed | |

| Output power | 0 – 200 amps | |

| Input power requirements (rated load) | 115/230 VAC, 1 Ø, 4.0 KVA, 50/60 Hz autoranging (no modifications necessary) | |

| Internal memory capacity | 100 weld programs | |

| Units of measurement Metric and Inch (selectable) | Metric and Inch (selectable) | |

| Program transfer | Solid state digital media (USB flash drive/memory key) | |

| Language selection | English, Spanish, German, French, others | |

| Settable override limits | Individually scalable overrides on each function 0 – 100% | |

Maximum open circuit voltage | 80 V | |

| Water and gas flow switches | Standard. Prevent damage to equipment and workpiece | |

| Data recording/printout | Operator ID, weld ID number, program number, material, od, wall thickness, date, time, weld head model, project, drawing, programmed parameters, etc. | |

| QC-parameter monitoring/recording/printout | Monitors and records any actual deviations from preprogrammed limits recording/printout | |

| Arc start type | HF | |

| Operating/storage temperature | Operating: -18 to 50°C (0 to 120° F) Storage: -25 to 60° C (-20 to 140° F) | |

| Humidity To 98% RH (non-condensing) | To 98% RH (non-condensing) | |

| Dimensions/weights | ||

| MODEL 514 POWER SOURCE | MODEL 904 CIRCULATOR | |

| Length | 48 cm (19�) | 48 cm (19�) |

| Width | 28 cm (11�) | 28 cm (11�) |

| Height | 32 cm (12.75�) | 20 cm (8�) |

| Weight | 24.5 kg (54 lbs) | 12.2 kg (27 lbs) |

Features

- Touch screen operation

- 200 amp output

- Up to 100 levels per program

- Stores 100 weld programs internally

- Wire feed capability for wire feed Heads

- Auto Program automatically generates procedures

- Programmable “override limits� provide supervisory control

- Weld parameter monitoring/reporting for QA/QC purpose

- Transfer programs and data to PCs using USB flash drive

- AutoTack automatically generates tack weld programs

- Head mounted membrane switches eliminate remote pendant (certain models only)

- Autoranging: 115/230 V input

- Password protection of key functions

- Built in printer allows program/QC report printout

Reviews

There are no reviews yet.