Description

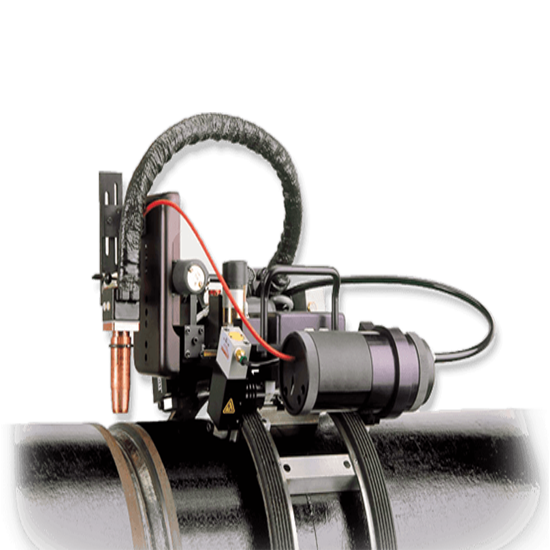

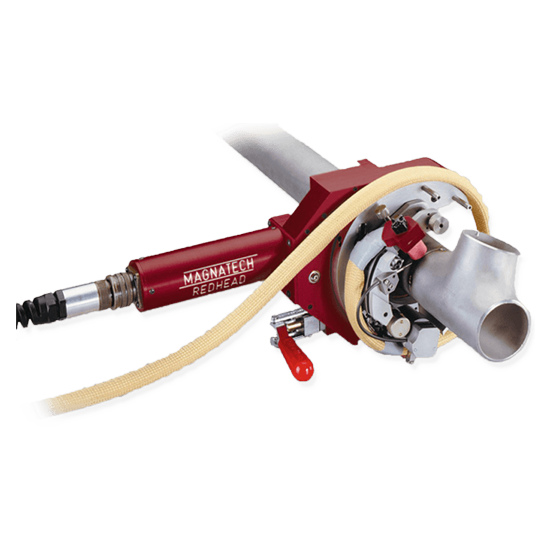

WELD HEADS 800 SERIES

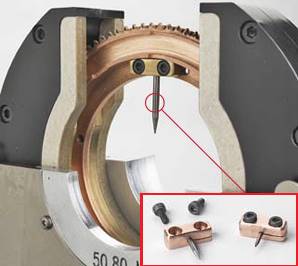

Tungsten holder allows field replacement in a minute. Virtual 360° circumferential contact of tungsten electrode guarantees positive arc starting. The 800 Series utilizes two inexpensive insert plates made of a heat/UV resistant material to protect the Head housing and mechanism. If necessary, they can be replaced in minutes.

1. Flip-top hinges open for final inspection of tube alignment prior to welding.

2. Indestructible stainless steel hinge provides rigidity for positive tube alignment.

3. Vernier adjustments allow clamping force to be optimally set. Prevents deformation of thin wall tube. 4 Molded silicone switch panel eliminates need for separate remote pendant. Dirt and moisture resistant.

WELD HEADS 800 SERIES

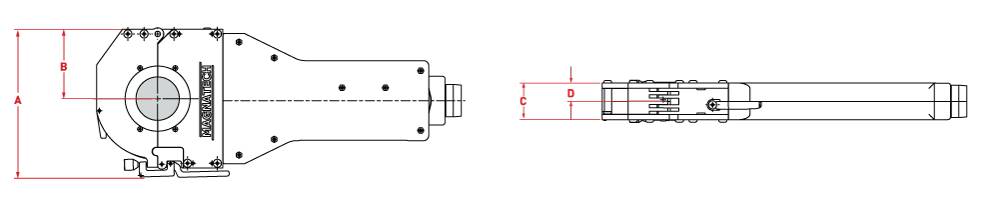

Dimensions Weights

| ||||||

| 805 | 810 | 820 | 830 | 840 | 860 | |

|---|---|---|---|---|---|---|

| Tube Diameter Range | 3-16 mm (.125-.625�) | 3-25 mm (.125-1.0�) | 6-51 mm (.25-2.0�) | 9-75 mm (.375-3.0�) | 12-102 mm (.5-4.0�) | 50-152.4 mm (2-6.0�) |

| RPM Range | 1.8 – 2.0 | 0.6 – 9.5 | 0.3 – 5.0 | 0.1 – 2.5 | 0.1 – 2.3 | 0.1 – 2.0 |

| Weight | 2.5 kgs (5.5 lbs.) | 3.2 kgs (7 lbs.) | 5.0 kgs (11 lbs.) | 6.4 kg (14 lbs.) | 8.2 kg (18 lbs.) | 10.0 kg (23 lbs.) |

| “A� | 91 mm (3.6�) | 124 mm (4.90�) | 175 mm (6.89�) | 202 mm (7.96�) | 231 mm (9.10�) | 297 mm (11.71�) |

| “B� | 36 mm (1.4�) | 62 mm (2.45�) | 83 mm (3.26�) | 96 mm (3.79�) | 110 mm (4.31�) | 144 mm (5.65�) |

| “C� | 31.3 mm (1.3�) | 42 mm (1.64�) | 43 mm (1.70�) | 43 mm (1.70�) | 43 mm (1.70�) | 43 mm (1.70�) |

| “D� 1 | 15 mm (0.6�) | 19.5 mm (.77�) | 19.5 mm (.77�) | 19.5 mm (.77�) | 19.5 mm (.77�) | 19 mm (.75�) |

1 Distance from nearest flush collet face to tungsten centerline. (Tungsten offset from center) | ||||||

Applications

- Extension cables allow use up to 23 m (75‘) from power supply

- Pre-ground tungsten electrodes

- Offset Tungsten Holders (Butt weld) allow use when axial clearance restrictions exist (such as short tangent fittings)

- Offset Tungsten Holders (Fillet weld) allow fillet (socket) welds to be made

Features

- WELD HEADS 800 SERIES 805, 810, 820, 830, 840, 860

- Collets for all tube sizes / fitting geometries

- Waterproof carry case standard<

- Bench mount bracket

- Internal weld head cooling standard

- Convenient flip-up view port allows final inspection before welding

- Encoder motors provide precise, repeatable speed regulation

- “Jam� detection/protection. If rotation stops for any reason, it is instantly sensed and power to the motor is immediately interrupted.

- No more damaged motors or drive trains<

- Standard 8 m (25’) hose pack length

- New rotation drive design tolerant of metal debris

- “Home� position switch automatically readies the head for removal following weld completion, and never requires adjustment

- Simple assembly makes field service straightforward

Reviews

There are no reviews yet.