Description

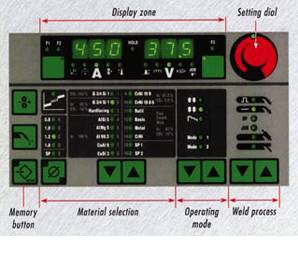

AUTOPROGRAM

The MPS 4000 comes with welding expertise already built-in. Power Source Controls stand out for their simplicity and ease of operation. Just set the wire diameter and type of material to access the factory preprogrammed optimized parameters that are stored in memory. The single-knob operation in synergic mode makes this job even easier. Power output is precisely synchronized with wire speed and is adjustable through its full range with the turn of a single knob.

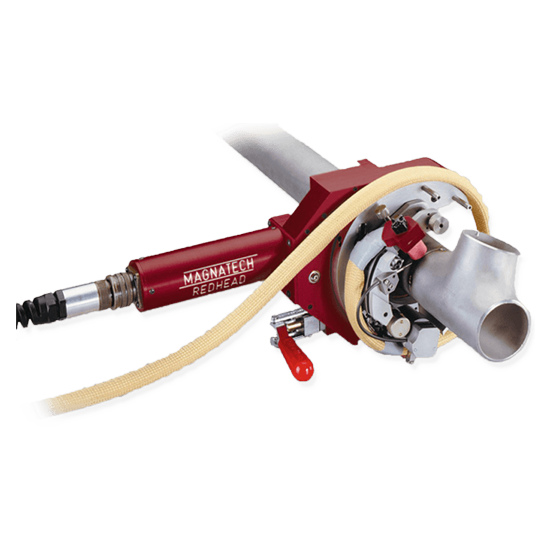

PIPELINER MPS 4000

| Specifications | ||||

|---|---|---|---|---|

| Application | For use with all Pipeliner GMAW/FCAW process weld heads | |||

| Functions controlled | Power module power output (standard and pulsed) Electrode feed speed Weld head rotation Weld head torch oscillation (linear standard, pendular optional) Weld head electronic cross-seam adjustment Weld head arc gap control | |||

| Internal memory capability | 80 synergic programs / 99 single point (voltage/wire speed) programs | |||

| MPS 4000 POWER SOURCE | ||||

| Output rating | 400 A 50% duty cycle, 320 A 100% duty cycle | |||

| Max. open circuit voltage | 70 V | |||

| Cos phi/efficiency | 0.99 / 88% | |||

| Input power requirements (Rated load) | Volts – 200/230/400/460 (autoranging); amperes 35 A; KVA 12.7; frequency 50/60 Hz | |||

| Degree of protection | IP23 | |||

Type of cooling | AF (forced Air) | |||

| Insulation class | F | |||

| Applicable electrical standards | IEC 974-1 (IP-23S); CSA; EMC 89/336/EEC; EN 60 974-1 | |||

| MODEL 712 WELD HEAD CONTROLLER | ||||

| Pendant cable length | 7.6 m (25’). Extension cables available | |||

| Degree of protection | IP23 (Excluding Remote Pendant) | |||

| MPS 4000R WATER CIRCULATOR | ||||

| Pump | Centrifugal | |||

| Cooling capacity | 2000 – 2300 W (at 20 EC/68° F) | |||

| Max. delivery capacity/pressure | 3.5 liters/min (0.9 gal/min) at 4.2 bar (60 psi) | |||

| Coolant volume | 5.54 liters (1.46 gallons) | |||

| Degree of protection | IP23 | |||

| MPS 4000 WIRE FEEDER | ||||

| Drive type | 4 roll (various groove geometries available) | |||

| Wire diameter | 0.8 – 1.6 mm (0.03 – 0.62”) | |||

| Wire feed speed | 0.5 – 22 m/min (20 – 866 ipm) | |||

| Degree of protection | IP23 | |||

| Dimensions/weights | ||||

| Power Module | Controller | Water Circulator | Wire Feeder | |

| Length | 72.5 cm (28.5”) | 72.5 cm (28.5”) | 72.5 cm (28.5”) | 65 cm (25”) |

| Width | 29 cm (12”) | 29 cm (12”) | 29 cm (12”) | 29 cm (12”) |

| Height | 47 cm (18.5”) | 23 cm (9”) | 23 cm (9”) | 41 cm (16”) |

| Weight | 35 kg (77 lb.) | 14.5 kg (32 lb) | 13 kg (29 lb) | 16 kg (35 lb) |

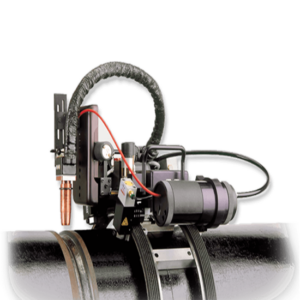

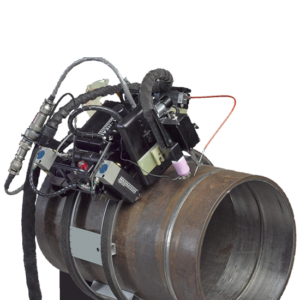

Applications

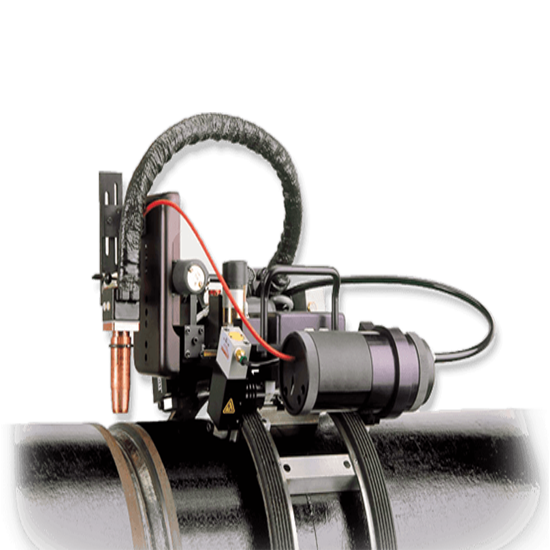

- Fossil and nuclear power plant construction/maintenance

- Steam generation equipment fabrication

- Gas and oil pipeline construction

- Marine pipeline construction

- Chemical/petrochemical facility construction and maintenance

- Large diameter vessel fabrication

- Shipyard Construction

Features

- Multi-pass welding of pipes

- Operates all variants of Magnatech Pipeliner weld Heads (FCAW/GMAW process)

- 400 Amp output

- Autoranging power input eliminates all internal modifications

- Pulsed/spray modes

- Integral switch prevents welding without torch gas flow

- Coolant recirculator with integral flow switch protection

- Meets applicable NEMA, CE, CSA standards

- Pendant allows remote operation

- Synergic operation of electrode speed/power output

- Factory optimized stored programs for most materials

- Program development service available for special alloys

- Outdoor job site usage (IP23 rating)

- Cart with bottle rack

Reviews

There are no reviews yet.